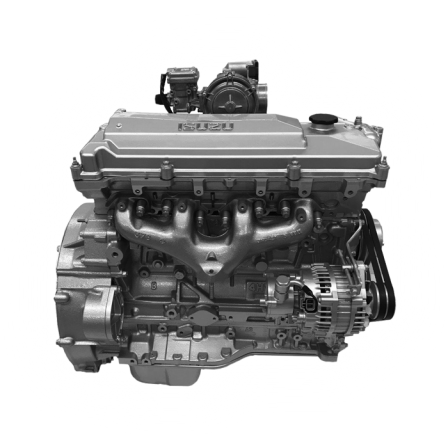

axle carrier assembly line is a type of industrial production in which prefabricated, replaceable parts are completed to assemble a product. The most basic assembly system consists of a simple conveyor belt that carries the product, like a toy, through a series of workstations until it is finished

How to prepare axle carrier assembly

The most basic assembly system consists of a simple conveyor belt that carries the product, like a toy, through a series of workstations until it is finished. More complex lines include feeder belts to transport parts to workstations along the line, used to build cars and other complex equipment. The development of the production line was the assembly of revolutionary production and led to the success of many important players in the Industrial Revolution.

The most basic assembly system consists of a simple conveyor belt that carries the product, like a toy, through a series of workstations until it is finished. More complex lines include feeder belts to transport parts to workstations along the line, used to build cars and other complex equipment. The development of the production line was the assembly of revolutionary production and led to the success of many important players in the Industrial Revolution.

Before the advent of the assembly line, when a commercial product was made, it was usually made by hand, from pieces made separately. Factory production was limited by the available space, as only a large number of products could be made at a time, and workers tended to see the project from start to finish. In the mid-nineteenth century, many food industry companies began to create something like an assembly line to make the process more efficient, but not quite simple. Products such as basic engines and steam engines were still made by hand.

The assembly line is designed to be very efficient and very cost effective. Workers focus on a small section of society as a whole, meaning they do not need extensive training. Pieces along a conveyor belt or set of belts used for workers, creating a continuous flow of the desired product. At the height of production, the Ford line launched a new car every three minutes, and modern lines can be even faster, especially when they combine automatic machines with human machines.

There are risks associated with an assembly line. The first danger is for workers, because repetitive movement can be harmful to the body. After World War II, growing awareness of the issue led to reforms in environmental collection. The second problem is that if it is produced at a workstation in production, it will affect the whole line, potentially suspending it to prove the situation. However, most modern manufacturers work with regular inspections to prevent this, and some manufacturers, especially from automobiles, are better off entering workers and thinking about ways to build assembly line and product.

Production line of axle carrier assembly

Typical rear axle carrier assembly line is a production process (often called a progressive assembly) in which parts (usually replaceable parts) are added to the workplace as a semi-finished assembly from the workstation, where the parts are produced until the final production . By mechanically moving parts to work and assembling semi-finished parts from the workstation to the workplace, a complete product can work faster and with less work, unless workers move the parts to a fixed piece for assembly.

Typical rear axle carrier assembly line is a production process (often called a progressive assembly) in which parts (usually replaceable parts) are added to the workplace as a semi-finished assembly from the workstation, where the parts are produced until the final production . By mechanically moving parts to work and assembling semi-finished parts from the workstation to the workplace, a complete product can work faster and with less work, unless workers move the parts to a fixed piece for assembly.

Assembly lines are common methods of collecting complex items such as cars and other transportation equipment, home appliances and electronic goods. The assembly lines are designed for the sequential organization of workers, tools, and machinery and parts. Minimize workers’ movement. All parts or assemblies using conveyor belts or motor vehicles such as lifts Elevators or attractions are used without manual transportation. Heavy lifting is done by machines such as overhead cranes or elevators. Every worker usually does a simple operation.

In one Axle carrier assembly system line, the car assembly is divided between several stations, all working simultaneously. When a station is finished with a machine, it takes it to the next step. With three stations, a total of three different machines can run at the same time.

Your comment submitted.